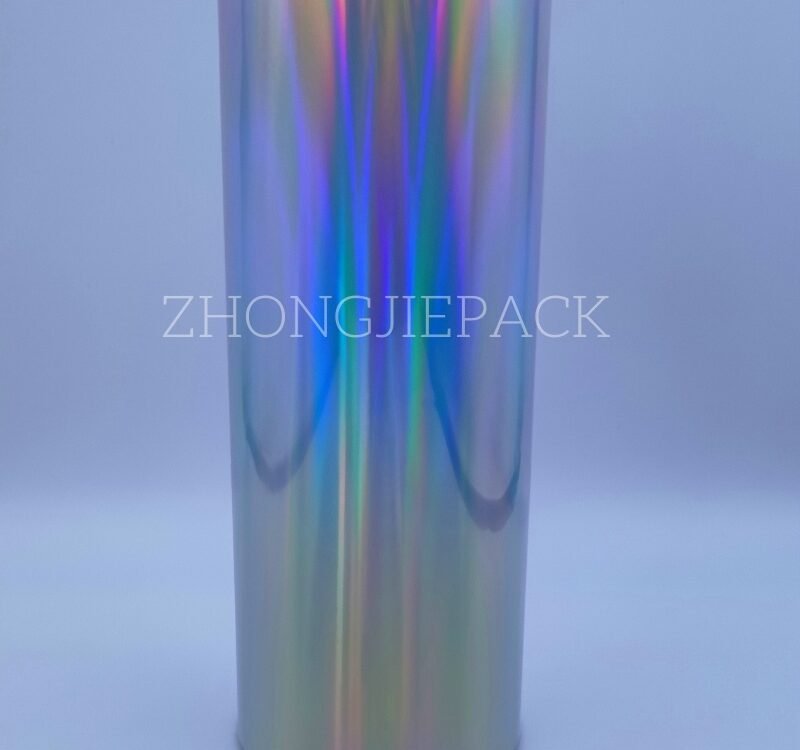

Holographic metallized film 2024

2023年12月10日

Security Holographic Rainbow Printable Film

2023年12月17日Introduction

Polyethylene terephthalate (PET) is a versatile material that can be used to create various types of films, including those with unique optical properties. One such property is the rainbow effect, which can be achieved through techniques such as thin-film interference or by incorporating color-changing additives. This guide provides a general overview of the production process for PET rainbow film.

1. Polyester PET Material Selection

To begin, start with high-quality PET resin, which is readily available in the market. Choosing a reliable supplier is crucial to ensure the desired properties and consistency of the film.

2. Coloring Agents

To create a rainbow-like effect, introduce colorants or additives that can produce iridescence. These may include interference pigments, holographic materials, or other specialized additives. These additives interfere with the reflection and transmission of light, resulting in the desired rainbow appearance.

3. Film Extrusion

Utilize a film extrusion process to melt the PET resin and shape it into a thin film. This process involves heating the resin and then forcing it through a die to achieve the desired film thickness. The extruder should be set to the appropriate temperature and speed to ensure proper melting and shaping of the resin.

4. Cooling and Solidification

Allow the extruded film to cool and solidify. The cooling process is crucial for setting the film’s structure and locking in the optical properties that create the iridescence. Proper cooling ensures that the film retains its desired rainbow effect.

5. Surface Treatment (Optional)

Depending on the desired effect, additional treatments may be applied to the film surface. Coatings or laminations can be used to enhance the rainbow appearance and provide additional protection to the film. These treatments can improve the film’s durability and visual appeal.

6. Cutting and Packaging

After the film has been cooled and solidified, it can be cut into the desired sizes and packaged for distribution. The thickness, usage, and specific color characteristics of the film will depend on the intended application and the desired properties of the final product. Rainbow films can be used for decorative purposes, packaging, or even in artistic and creative projects.

It is important to note that the specifics of production methods and materials can vary widely based on proprietary technologies developed by manufacturers. If you are interested in producing or purchasing PET rainbow film, it is advisable to consult with materials experts or manufacturers in the field for the most up-to-date and accurate information.

Conclusion

PET rainbow film is a visually striking material that can be used for various applications. By carefully selecting high-quality PET resin, incorporating iridescent additives, utilizing film extrusion, and applying optional surface treatments, it is possible to produce a PET rainbow film with the desired optical properties. Whether used for decorative purposes, packaging, or creative projects, PET rainbow film adds a vibrant and captivating element to any application.

https://www.zhongjiepack.com/product/rainbow-film/